Frequently Asked Questions

How is Linergy currently regulated?

Linergy operates under an Integrated Pollution Prevention and Control (IPPC) permit issued by the Northern Ireland Environmental Agency (NIEA). The permit covers all actual and potential environmental impacts. In order to retain the permit, emissions from Linergy are tested and approved by the NIEA which has certified Linergy as operating with Best Available Technology. This means that it operates to the highest standards in its rendering process to control all environmental impacts.

Are there any other ways in which Linergy is regulated?

Ensuring a robust approach to self regulation is an important way in which Linergy achieves its high environmental standards. The co-location of businesses within Granville Industrial Estate ensures high standards, with two major agri-food companies, Linden Foods and Dunbia, being our closest neighbours (located within 100 metres). With over 1,400 staff working on these sites every day, Linergy is very conscious of its responsibilities. These companies’ customers include Marks and Spencer, Co-Op, Sainsbury’s, Supervalu, McDonalds, Dunnes Stores and Tesco. Each customer regulates through unannounced audits which have a significant environmental aspect. Linergy and its shareholders, Linden Foods and Dunbia, are very conscious of the commercial impact that achieving anything short of excellence in its approach to environmental standards and regulation would have on these customers.

What procedures do you have in place to achieve the highest environmental standards?

Linergy employs a fully trained Environmental Manager to oversee compliance and monitoring of environmental standards. The key component to ensure compliance is the Pollution Prevention Control (PPC) permit, under which Linergy operates. This permit sets out emission limits on all media which leaves the factory, including air and water and includes operating conditions which must be adhered to. These emissions are monitored throughout the year and analysis is carried out by independent laboratories. Each time a sample is analysed, the results are sent to the Northern Ireland Environment Agency (NIEA) to verify it is within regulatory limits. In addition, Linergy continuously records all processing activities via a Supervisory Control and Data Acquisition (SCADA) control system which provides real time data on plant and equipment which can be remotely monitored to ensure the facility is working to optimal environmental efficiencies. Linergy also operates under a fully documented Environmental Management System (EMS) which sets out procedures for all aspects of operations on the site, from the intake of raw materials, through the entire process and on to the final dispatch of processed materials. The EMS has been developed in conjunction with NIEA to ensure all aspects of the operation are incorporated to the highest standards. It is acknowledged by NIEA that the facility operates according to Best Available Technology (BAT).

Do you have a complaints procedure in place?

Linergy operates a comprehensive complaint procedure. When a complaint is received by Linergy, the details of the complaint are entered onto a recorded log and the supervisor in charge at that time will check all process conditions and equipment to ensure they are working within regulatory limits. If it is found that there is an issue, the maintenance department will be informed and the issue will be rectified immediately. The Environmental Manager will then collect all details of equipment operating conditions from the Supervisory Control and Data Acquisition (SCADA) control system, collect weather details and send a full report to NIEA providing a commentary on all aspects of the complaint. If it is found that a technical problem did cause an issue, a report will be made to NIEA under the terms of the Prevention Control (PPC) permit which will include the reasons for the malfunction and measures intended to prevent a reoccurrence of such an event.

What is a thermal oxidiser and how is it used in the rendering process?

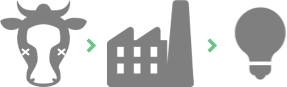

To destroy the volatile compounds (VCs) in the exhaust vapours from the rendering process a thermal oxidiser is used. Thermal oxidation is a combustion process in which the VCs within the exhaust vapour react with oxygen in a temperature controlled environment to create an oxidation reaction. This chemical reaction is what reduces the pollutants in the exhaust gas to an innocuous emission (CO2, water vapour, and heat) before it is released to the atmosphere. Heat from this process is not wasted. Hot air from the reaction chamber enters a waste heat boiler which in turn generates steam for the cooking process and other ancillary uses in the factory. Heat is again recovered after this process by passing the hot air through a heat exchanger which heats the initial vapours entering the thermal oxidiser. This allows the whole process to be very efficient. Innocuous emissions are then passed to the atmosphere via the flue on site.